VORTEX ECO Wastewater Treatment Plant

The acclaimed VORTEX™ Eco Electric sewage treatment plant is the most advanced system in the UK. Much cheaper to run than all non-electric treatment plants

It is the only fully adjustable sewage treatment plant in the UK, ideal for low occupancy situations, which cause massive problems for most treatment plants. You can turn it up and turn it down using a simple hand-turn valve. It also uses the least electricity for the highest effluent standard.

It is the ideal sewage treatment system for 'ECO', sustainable and 'GREEN' sewage treatment projects. Non-Electric sewage treatment plants, though great in principle, can cost a lot to run, as the filtration bags and media require annual replacement and this can cost up to £150/year in materials alone with some makes.

Much cheaper than a new septic tank and soakaway installation - the VORTEX™ sewage treatment system can discharge straight to a ditch, stream, river, surface water drain or land drain.You don't need an expensive soakaway drainfield.

BEWARE - In-Tank septic tank conversions advertised on the internet require a Permit from the Environment Agency before installation.

Unique Features of the VORTEX™ Sewage Treatment System

- Outstandingly clean effluent treatment - up to 98.9% pollutant reduction

- The most efficient sewage treatment plant. Click here to see How the VORTEX uses such a small amount of electricity.

- Odourless - complete aerobic digestion throughout the sewage treatment plant

- Very small footprint enables installation where space is limited.

- The VORTEX™ has a unique debris screen - tampons do not cause serious problems for the treatment process, as with other similar sewage plants.

- Unique SLUDGE MANAGEMENT SYSTEM - enhances treatment performance and reduces the plant servicing requirements and cost.

- Has a visual alarm for blower malfunction.

- The VORTEX™ sewage treatment system recycles its own waste products for re-digestion

- No Primary Settlement Tank - No Primary Tank Sewage Odour.

- Simple and cheap treatment plant to maintain.

- Top Quality linear motor compressor. These compressors are much more expensive than the cheaper compressors used by other treatment plant manufacturers, but they are very quiet, use very little electricity and CAN be repaired.

- Cheap, easy installation - Very shallow installation models available

- 10 year tank warranty

- Can accept raw sewage pumped into it if required.

- Versatile inlet depths - Vortex™ wastewater treatment plants can be supplied from 150mm up to 900mm inlet invert levels.

- EN 12566-3 2005 Certificate available below - see Downloads.

- Unbeatable ammonia reduction - incredibly averaging 0.4mg/L. Very important for sensitive watercourses.

- Accepted by the Environment Agency for discharge to streams, rivers and ditches

- NO CONCRETE - Sand Backfill only, for dry sites. Click here for the easy Installation Manual

- It has a WET PIT TEST CERTIFICATE for high groundwater sites

| Electricity required | YES - lowest of any electrical treatment plant |

| Emptying Interval | Annual |

| Primary tank | NO |

| Internal electrical moving parts | NO |

| Concrete backfill | NO - on dry sites YES - on wet or Clay sites |

| Performs during intermittent use (holiday lets, etc.) | NO |

| Visually intrusive (large lids, kiosk, etc.) | NO |

| Expensive servicing | NO |

| Tank Warranty period | 10 Years |

| Easy Installation | YES |

How the VORTEX™ Sewage Treatment Plant Works

The Vortex Wastewater Treatment Plant Process

-

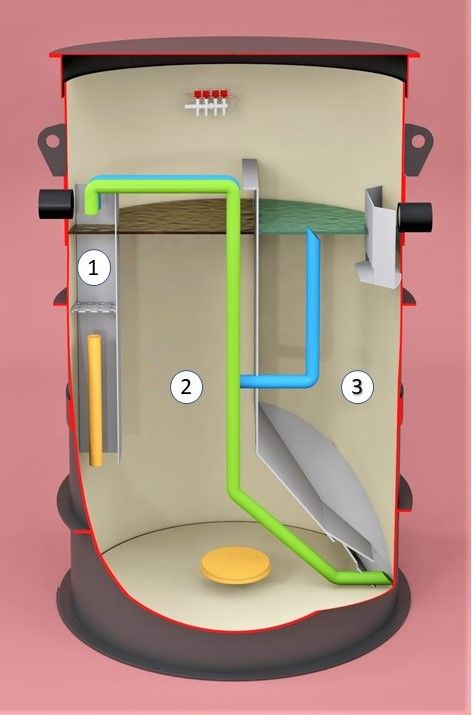

Wastewater from the building enters the Vibro Screen box (1). Here coarse air bubbles are used to physically break down solid matter in the sewage and form a mixed liquor with the water prior to treatment.

-

The mixed sewage liquor flows into the Aeration Chamber for treatment (2). A bacterial culture is present in the Aeration Chamber which digests the pollutants in the wastewater. The bacterial culture must have a constant oxygen supply and this is provided by a fine bubble diffuser at the base of the tank.

-

The mixed sewage liquor then flows into the Clarification Chamber (3) where it is able to separate into clear, treated sewage effluent and sludge. The clear effluent is able to flow past the scum baffle and out of the tank.

The Sludge Management System (SMS)

-

In the Clarification Chamber sewage sludge accumulates at the bottom (

-

settled sludge) and top (floating sludge) of the tank.

-

Air from the blower is spurred from the air regulator valves to two sludge return pipes - one for Floating Sludge and one for Settled Sludge.

-

This creates a vacuüm that sucks the sewage sludge from the bottom of the Clarification Chamber back to the Aeration Chamber constantly.

-

It also creates a vacuum that sucks the Floating Sludge, periodically, by use of a timer, from the top of the Clarification Chamber

Automatic Floating Sludge Return (FSR)

In all ASP sewage treatment systems, floating sludge accumulates at the top of the Clarification Chamber. This sludge must be periodically returned to the Aeration Chamber, manually, with all other ASP type plants. All our Vortex plants are fitted with an Automatic FSR as this makes the process automatic.

The Automatic FSR Kit enables the Vortex to automatically recycle the floating sludge in the Clarification Chamber back to the Aeration Chamber of the plant, negating the need for the owner to manually manage the sludge build up in the tank.

No other ASP sewage treatment plant has this ability to manage its own sludge.

Principles of the VORTEX™ wastewater treatment system process

The Vortex™ has an advanced sludge management system not found in any other sewage treatment system in the UK.

The ONLY electrical component is a small, external linear motor compressor which operates ALL the treatment plant process stages. There are no pumps, motors or any moving parts within the plant. It has a fail-safe alarm as standard.

Incoming sewage is screened to prevent accidental non-degradable products entering the plant's digestion chamber. The innovative Vibro-Screen™ allows organic sewage solids to enter the tank without problems. This is an advanced feature not found on other treatment plants.

The screened sewage is aerated and a microbial 'soup' develops that digests the pollutants and organic matter in the sewage. These beneficial microbes are constantly topped up with the microbes that settle out at the bottom of the final settlement tank,as part of the sludge management system, ensuring a constant 'friendly bacteria' supply for the treatment plant process. There is no need to add extra bacteria at all, as is the case with some other treatment plants.

Benefits of the Unique Sludge Management System

When the treated sewage enters the final settlement chamber, activated sludge bacteria settle out at the bottom. These beneficial live microbes are constantly returned to the digestion chamber to mix with the raw sewage and boost the performance of the treatment plant system.

The bacterial scum or crust that forms on the top of the effluent in the clarification chamber is also able to be returned through a pipe to the incoming sewage in the Vibro-screen. This is a superb innovation unique to the Vortex™. Other activated sludge sewage plants need the removal of this sludge crust and its return to the biozone,manually, by hand, at regular intervals. Click on the video below to see the VORTEX™ sludge management system in action. There are no more pumps involved - it is activated by the same small blower that aerates the plant. This saves a lot of unpleasant work for both the owner and the service engineer, resulting in lower cost servicing bills.

Settled, clean effluent in the central trough then discharges to the watercourse or soakaway.

The VORTEX™ is an Activated Sludge Sewage Treatment Process system with fail-safe and sludge management features not found in any UK manufactured sewage treatment systems.

Superb Effluent Quality

This is the average attained during its EN 12566-3 2005 Test

| BOD (mg/L) | Suspended Solids (mg/L) | Ammonia (NH3) (mg/L) |

| 8.5 | 15.2 | 0.4 |

Well below the Environment Agency Requirement of:

| BOD (mg/L) | Suspended Solids (mg/L) | Ammonia (NH3) (mg/L) |

| 20 | 30 | 20 |

The above unbeatable figures enable the VORTEX™ to be installed in very sensitive areas where no other treatment system in the UK would be acceptable to the Environment Agency or SEPA.

Activated Sludge Plants (ASP's) are known to suffer when underloaded. They are either blowing the maximum amount of air, when 'on' or none when 'off'. However, the VORTEX™ sewage treatment system has a unique air regulation valve which, by turning down the air supply valve, reduces the air supply to the diffuser. This allows the treatment plant to be 'turned down' to suit lower populations. Below are the EN 12566-3 Test Results for normal 100% flow rate and underloading at 50%.of the flow rate.

| Flow Rate | 100% | 50% |

| BOD | 8.5 | 5.8 |

| Suspended Solids | 15.2 | 10.6 |

| NH3 | 0.4 | 0.17 |

See DOWNLOADS for more VORTEX sewage treatment system information

Very Low Electricity Use

VORTEX™ Sewage Treatment Plant Downloads

VORTEX™ Sewage Treatment Plant CE CERTIFICATE

Tech Spec. Data Download for VORTEX™ 4 to 30 person sewage treatment systems

INSTALLATION MANUAL for the VORTEX

Environment Agency Rules for Septic Tanks and Sewage Treatment Plants

British Water codes of Practice for Sewage Disposal

UK distributors wanted for this unbeatable VORTEX® ECO wastewater treatment system.