Septic Tanks - Systems, Products, Facts and Advice

Types of Septic Tank Systems Available

There are various types of septic systems. They consist of an underground tank in differing shapes and sizes, which then connects to a secondary soil treatment system, usually a land drainage system in the form of a soakaway or drainfield, or a mound soakaway.

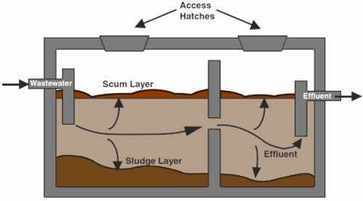

How a Septic Tank works

Raw sewage and wastewater from baths, kitchens, etc. discharges into the septic tank, where the solids are separated from the liquid waste. Fats and oils float to the top and form a crust layer. Faeces and food scraps sink to the bottom and form a sludge layer. Anerobic bacteria which are natural colonisers in the tank "digest" this sludge by up to 70%. The dirty septic water flows to a soakaway or drainfield. Baffles or 'T' pipes in the tank hold back the floating crust and prevent it from entering the outlet. In order that the sludge and crust layers do not become too deep, septic tanks should be emptied annually. This also prevents a higher and higher concentration of suspended solids washing out into the soakaway. Solids can block the air spaces in the soil drainage system, creating a drainage problem and the effluent will not be able to soak away or be treated by the natural soil bacteria.

Variations in the different tanks

Vent Pipe Installation

Vent pipes should be installed from the first and second chambers for venting the gases, mainly methane and hydrogen sulphide, produced by the sludge. Strong covers should always be placed completely over the tank to avoid children / animals falling in. There are many cases of septic tank covers collapsing and many people have been killed as a result.

Onion or Traditional rectangular tanks?

Nowadays, septic tanks are made in GRP and polyethylene which commonly are spherical in shape with a narrow shaft at the top to a manhole cover at ground level. These tanks do not produce the same quality of effluent as traditional brick, concrete or GRP two chamber tanks and cannot be placed in front of many septic tank conversion units, including the FilterPod and BioKube.

Installation of the tanks

Further sewage treatment is always required

The alternative method for further treatment is to install a FilterPod non-electric sewage treatment plant, QUANTUM sewage treatment plant or VORTEX after the tank. The effluent can then be discharged to a watercourse or ditch.

Further Information

- How aseptic tank works

- Types of septic systems

- Variations in tanks

- Venting the system

- 'Onion' or Traditional shaped tank?

- What size septic tank do I need?

- How often should it be emptied?

- Can the septic tank accept roofwater?

- What about bleaches and detergents?

- Soakaway drainage field advice, design and installation

- Problems with Septic Systems

- Septic Tank Surveys

- Septic tank installation

- Differences between septic tanks and sewage treatment plants